When it comes to choosing the right industrial flooring solution, understanding the vulcanised vs non-vulcanised rubber mats difference is extremely important — especially for dairy farms, gyms, warehouses, and industrial facilities.

Rubber mats are widely used for safety, durability, anti-slip performance, and heavy load resistance. However, not all rubber mats are manufactured the same way. The manufacturing process directly affects strength, lifespan, and long-term cost.

In this guide, we will explain:

- What vulcanised rubber is

- What non-vulcanised rubber is

- Key differences between both

- Which one is better for bulk and industrial buyers

- How to choose the right rubber mat manufacturer

If you are a global bulk buyer, this comparison will help you make an informed investment decision.

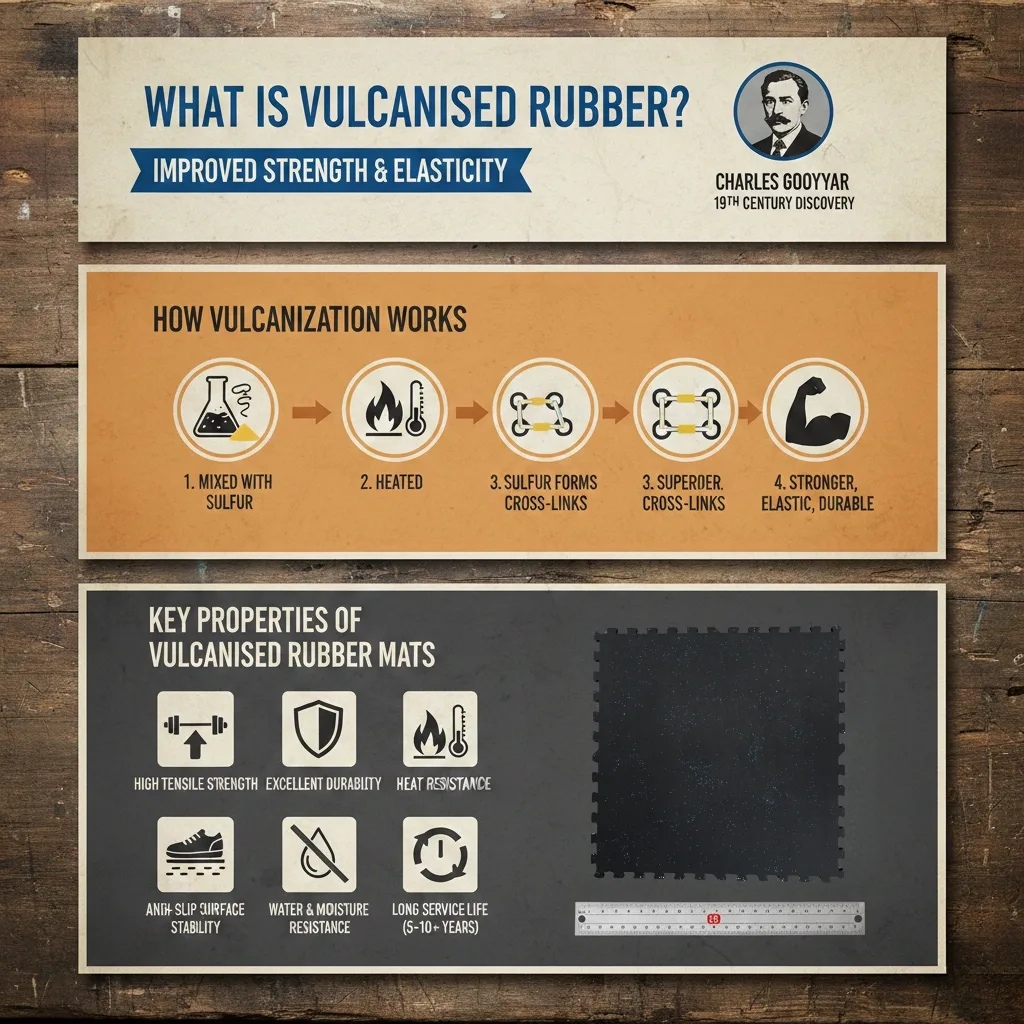

What is Vulcanised Rubber?

Vulcanised rubber is rubber that has been chemically treated with heat and sulfur to improve its strength and elasticity. This process was discovered by Charles Goodyear in the 19th century and revolutionized the rubber industry.

How Vulcanization Works

During vulcanization:

- Raw rubber is mixed with sulfur.

- The mixture is heated under controlled temperature.

- Sulfur forms cross-links between polymer chains.

- The rubber becomes stronger, more elastic, and more durable.

Key Properties of Vulcanised Rubber Mats

- High tensile strength

- Excellent durability

- Superior heat resistance

- Anti-slip surface stability

- Water and moisture resistance

- Long service life (5–10 years or more in heavy-duty conditions)

Because of these properties, most heavy duty rubber mat manufacturers prefer vulcanised rubber for industrial and export-quality mats.

What is Non-Vulcanised Rubber?

Non-vulcanised rubber (also called raw or uncured rubber) is rubber that has not undergone the sulfur heat treatment process. It remains softer and more flexible but lacks structural strength.

Manufacturing Process

In this case:

- Rubber is processed into sheets or mats.

- No cross-link bonding is created.

- The material remains softer and less resistant to heat and pressure.

Key Properties of Non-Vulcanised Rubber Mats

- Lower production cost

- Higher flexibility

- Reduced durability

- Shorter lifespan (1–3 years in heavy use)

- Limited heat resistance

Non-vulcanised mats are generally used for temporary or low-load applications.

Vulcanised vs Non-Vulcanised Rubber Mats: Quick Comparison

| Feature | Vulcanised Rubber Mats | Non-Vulcanised Rubber Mats |

| Durability | Very High | Moderate |

| Lifespan | 5–10 Years | 1–3 Years |

| Heat Resistance | Excellent | Low |

| Load Bearing Capacity | High | Limited |

| Moisture Resistance | Strong | Moderate |

| Cost | Slightly Higher | Lower |

| Industrial Suitability | Highly Recommended | Limited |

From a long-term investment perspective, vulcanised rubber mats clearly offer better performance for bulk industrial buyers.

Which Rubber Mat is Better for Different Industries?

Choosing between vulcanised and non-vulcanised rubber mats depends on usage type. Let’s break it down industry-wise.

🐄 Dairy Farms & Livestock Flooring

Dairy farms require:

- Anti-slip surface

- High weight-bearing capacity

- Comfort for animals

- Easy cleaning

- Long-term durability

Vulcanised rubber mats are ideal for dairy applications because they withstand constant animal movement, moisture exposure, and heavy loads.

Non-vulcanised mats may deform under pressure and wear out faster.

Recommendation: Vulcanised rubber mats for long-term dairy flooring solutions.

🏋️ Gyms & Fitness Centers

Gym flooring needs:

- Shock absorption

- Impact resistance

- Noise reduction

- Anti-slip grip

Vulcanised rubber mats perform better under heavy gym equipment and dropped weights. They maintain shape and provide long-term structural stability.

Non-vulcanised mats may compress over time.

Recommendation: Vulcanised rubber flooring for commercial gyms.

🏭 Industrial & Warehouse Use

Industrial facilities demand:

- Chemical resistance

- Machine vibration control

- Worker safety

- Long lifespan

Vulcanised rubber offers superior resistance to oil, grease, and mechanical stress.

Recommendation: Always choose vulcanised rubber mats for industrial environments.

🏠 Temporary or Low Budget Applications

If the requirement is short-term usage, light traffic, or cost-sensitive projects, non-vulcanised rubber mats can be a practical option.

However, replacement frequency should be considered in total cost evaluation.

Cost vs Long-Term Investment

Many bulk buyers initially focus only on price per square meter. But the smarter approach is calculating long-term ROI.

Vulcanised Rubber Mats

- Higher upfront cost

- Minimal maintenance

- Longer lifespan

- Lower replacement frequency

Non-Vulcanised Rubber Mats

- Lower initial cost

- Faster wear and tear

- Higher long-term replacement cost

For export buyers and industrial clients, vulcanised mats usually provide better value over time.

How Bulk Buyers Should Choose the Right Rubber Mat

If you are sourcing from a rubber mat manufacturer, consider these factors:

- Thickness (15mm, 17mm, 20mm etc.)

- Surface pattern (Diamond top, bubble top, groove bottom)

- Load-bearing capacity

- Anti-slip rating

- Weather resistance

- Manufacturing standards

- Export packaging quality

For dairy and animal applications, patterned surfaces like diamond top or bubble top bottom groove improve grip and drainage.

Why Global Buyers Prefer Vulcanised Rubber Mats

International importers and distributors prefer vulcanised rubber mats because:

- They meet industrial durability standards

- They handle extreme weather conditions

- They maintain structure during shipping

- They offer higher tensile strength

- They provide long-term customer satisfaction

For exporters and bulk suppliers, supplying vulcanised rubber mats enhances brand reputation and reduces customer complaints.

Frequently Asked Questions (FAQs)

The main difference is the manufacturing process. Vulcanised rubber is heat-treated with sulfur, making it stronger and more durable, while non-vulcanised rubber remains softer and less resistant to wear.

Yes, vulcanised rubber mats offer excellent moisture and water resistance, making them ideal for dairy and industrial use.

Vulcanised rubber mats typically last 5–10 years under heavy-duty use, compared to 1–3 years for non-vulcanised mats.

Yes, they have a lower initial cost but may require more frequent replacement.

Vulcanised rubber mats are best for dairy farms due to their durability, anti-slip surface, and heavy load capacity.

Final Verdict: Which One Should You Choose?

When comparing vulcanised vs non-vulcanised rubber mats, the choice depends on application and budget.

If you need:

- Long-term durability

- Heavy load resistance

- Industrial performance

- Export-quality strength

Then, vulcanised rubber mats are the superior option.

Non-vulcanised rubber mats are suitable for temporary or light-duty applications where cost is the main concern.

For bulk buyers, distributors, and industrial clients, investing in vulcanised rubber mats ensures better performance, reduced maintenance, and higher return on investment.

Looking for a Reliable Bulk Rubber Mat Manufacturer?

If you are searching for a trusted rubber mat manufacturer supplying heavy-duty vulcanised rubber mats worldwide, choose a company that focuses on quality manufacturing, export standards, and durable surface patterns designed for dairy, gym, and industrial use.

Contact Vedansh Industries today to get bulk pricing and export-grade rubber mat solutions tailored to your requirements.